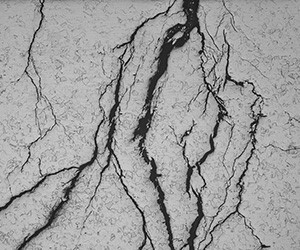

Under certain conditions, stress cracking corrosion can initiate and spread quickly. As a result, fittings that appear in good condition can fail suddenly and catastrophically.

Such failure can present a significant safety risk to personnel working in harsh environments such as those encountered on offshore platforms where high-pressure instrumentation fittings are often used. It can also lead to unexpected downtime and associated maintenance costs.

So, understanding the means of mitigating or preventing stress cracking corrosion in instrumentation applications is an important topic. And it is an area where Parker brings considerable research and expertise for its partners.

What is stress cracking corrosion?

The definition of stress cracking corrosion (SCC) – according to NACE International, the worldwide corrosion authority – is the cracking induced from the combined influence of tensile stress and a corrosive environment. Platform engineers are often familiar with problems associated with stress overloads, and indeed with other corrosive forms such as pitting or crevice degradation. But SCC is unique because it combines the two aspects of stress and corrosion, making it a phenomenon worthy of closer study.

For SCC to occur, there needs to be a corrosive media, the presence of tensile stresses on the material surface as well as a material susceptible to this failure mode. Consequently, the absence of any one of these factors can provide effective mitigation or elimination of this form of corrosion.

As such, it is vital to take a holistic view of each of these factors when considering ways of mitigating this form of corrosion.