Developments in digital technology have opened new possibilities for water sensing, offering unprecedented access to a raft of real-time, high accuracy data without the drawbacks associated with many conventional sensor types. By utilising these devices in their water treatment processes, operators can count on greatly improved measurement of many of the key parameters entailed in the treatment of both household and industrial effluent.

This article looks at some examples of the new digital sensing technologies on offer and explains how they are already delivering real benefits for water utilities.

They say prevention is better than cure and that’s doubly true in the wastewater industry.

The need to meet stringent environmental legislation and maximise profitability through reduced operating costs is incentivising many operators to find ways to better understand what’s happening in their processes.

Developments in digital water sensing technology are offering unprecedented access to a raft of real-time, high accuracy data without the drawbacks associated with many conventional sensor types. By utilising these devices, operators can count on greatly improved measurement of many of the key parameters entailed in wastewater and industrial effluent treatment.

Continuous automatic measurement beats manual methods hands down

The last few years have seen purely analogue systems increasingly being superseded by digital measurement devices offering expanded data gathering and communications capabilities.

As well as avoiding pollution incidents, the improved access to timely data delivered by these devices is enabling users to make informed decisions that can lead to a step change in performance, efficiency and maintenance.

Continuous measurement cuts costs

Continuous automatic measurement beats manual methods hands down. In contrast to traditional manual sampling methods, continuous online analyser systems enable samples to be automatically measured and analysed at the point of sampling, giving real-time indication of current process conditions.

Benefits include reduced failures and maintenance issues, such as unexpected shutdowns or increased plant maintenance. Others include reduced delays and failures that can affect treatment efficiency and regulatory compliance.

…it quite literally pays to use the best available technology to minimise the risk of any infringements

As well as reducing the need for operators to make sometimes costly interventions, automatic continuous monitoring can also help to reduce levels of sludge. Using the latest digital dissolved oxygen sensors in activated sludge systems, for example, can offer much tighter control of dissolved oxygen levels, matching them to actual oxygen demand and helping to ensure the right conditions needed to optimise aeration process efficiency. Moreover, with aeration processes accounting for over half of a plant’s energy costs, ensuring tight control of dissolved oxygen can also help operators to realise substantial energy cost savings.

Continuous measurement helps compliance

With both Ofwat and the Environment Agency taking an increasingly tough stance on the quality of wastewater discharged to the environment, it quite literally pays to use the best available technology to minimise the risk of any infringements.

The need to measure phosphate levels was behind Severn Trent’s decision to install 120 Aztec 600 phosphate analysers in wastewater treatment plants throughout its operating area. With the ability to accurately measure phosphate levels down to 0.0016ppm, the analysers are helping to ensure that the company keeps within the increasingly stringent consent limits set by the UK Environment Agency.

Operating as part of a dosing control system alongside ammonia analyzers, iron analyzers and turbidity monitors, the phosphate analysers have reduced the company’s reliance on manual sampling.

Analytical sensors in wastewater treatment face some of the toughest operating conditions of any measurement instrument.

Connected to Severn Trent Water’s eSCADA system, the analysers provide continuous real-time data, including any alarms generated by issues such as high phosphate levels. Combined with the data obtained from other instruments, such as ammonia and turbidity analyzers, Severn Trent has a complete picture of its water quality at all times.

Obtaining real-time data on phosphate levels helps ensure the company never strays outside its consented limits. The data is also a boon when it comes to planning future investments designed to further improve effluent quality.

React or predict?

Analytical sensors in wastewater treatment face some of the toughest operating conditions of any measurement instrument.

With these devices often in constant contact with substances ranging from toxic liquids through to sewage sludge, it is not surprising that regular maintenance and inspection regimes are needed to ensure continued accuracy.

Until relatively recently, carrying out these regimes relied on a combination of manufacturer guidelines, established practice and, to some extent, guesswork. Operators could put together a maintenance schedule based on the likely operational lifespan of a device, coupled with the effects of exposure to the medium being measured. What they often couldn’t predict, however, was the impact of any unforeseen variations, either in the performance of the device or the substance it was in contact with.

When coupled with the arrival of next generation digital transmitters, digital sensors are helping to transform water quality analysis

Furthermore, the effectiveness of the maintenance and inspection routines relied on having the staff available to carry them out. With a growing number of companies increasingly faced with shrinking engineering teams stretched across multiple sites, there has been a risk that these routines are not always carried out to plan.

In both cases, there is a risk of measurement performance being affected by deteriorating accuracy or complete instrument failure, increasing the potential for a breach of consent levels and the likelihood of stiff financial penalties being imposed.

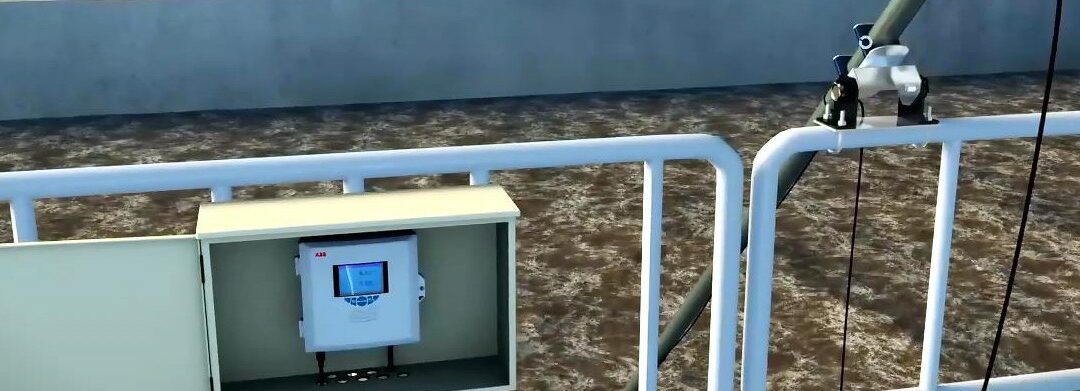

With the advent of digital sensors, these challenges are being overcome. When coupled with the arrival of next generation digital transmitters, plus the arrival of remote condition monitoring, digital sensors are helping to transform water quality analysis, not least by enabling operators to use the data they generate to create smart maintenance routines. This data can include not just the water quality parameter being measured, but also device-level diagnostics, opening new possibilities for assessing performance and pinpointing problems before they can develop.

By using this data to create tailored maintenance routines, operators can ensure that engineers are only dispatched to site when necessary. As well as greatly enhancing the reliability of the installation, the availability of this ‘deeper data’ can also reduce the cost of operation and maintenance, enabling digital sensors to offer a much lower total cost of ownership than their analogue counterparts.

Another important factor is simplicity. With skilled operators being at a premium, there is a need to ensure that devices can be used easily. This includes not just operation, but also setting up, fine-tuning and fault-finding.

For this reason, instrument manufacturers have worked to minimise the complexity of their devices, enabling them to be used by even the least experienced operators. Our latest generation of digital transmitters feature our ‘EZLink’ plug and play technology, which enables them to be quickly and easily connected to our digital sensors, with all necessary information and settings automatically uploaded.

Furthermore, because these transmitters use a common operating interface, operators trained on one device can use the same knowledge to program and operate any of our other instruments and analysers with minimum need for further training.

Summary

The possibilities offered by digital devices in people’s everyday lives when it comes to immediate access to live data is increasingly leading to an expectation of the same level of performance in the workplace.

More information, better control, less cost, more focused maintenance, fewer breakdowns and a substantially reduced chance of pollution incidents – when it comes to wastewater treatment, the all-round benefits offered by the latest generation of online digital sensors and analyser systems make them the ideal solution for water companies needing to find ways to keep a continuous eye on process performance and regulatory compliance.

For more information on ABB products please contact us using the form below and a member of our team will be in touch.